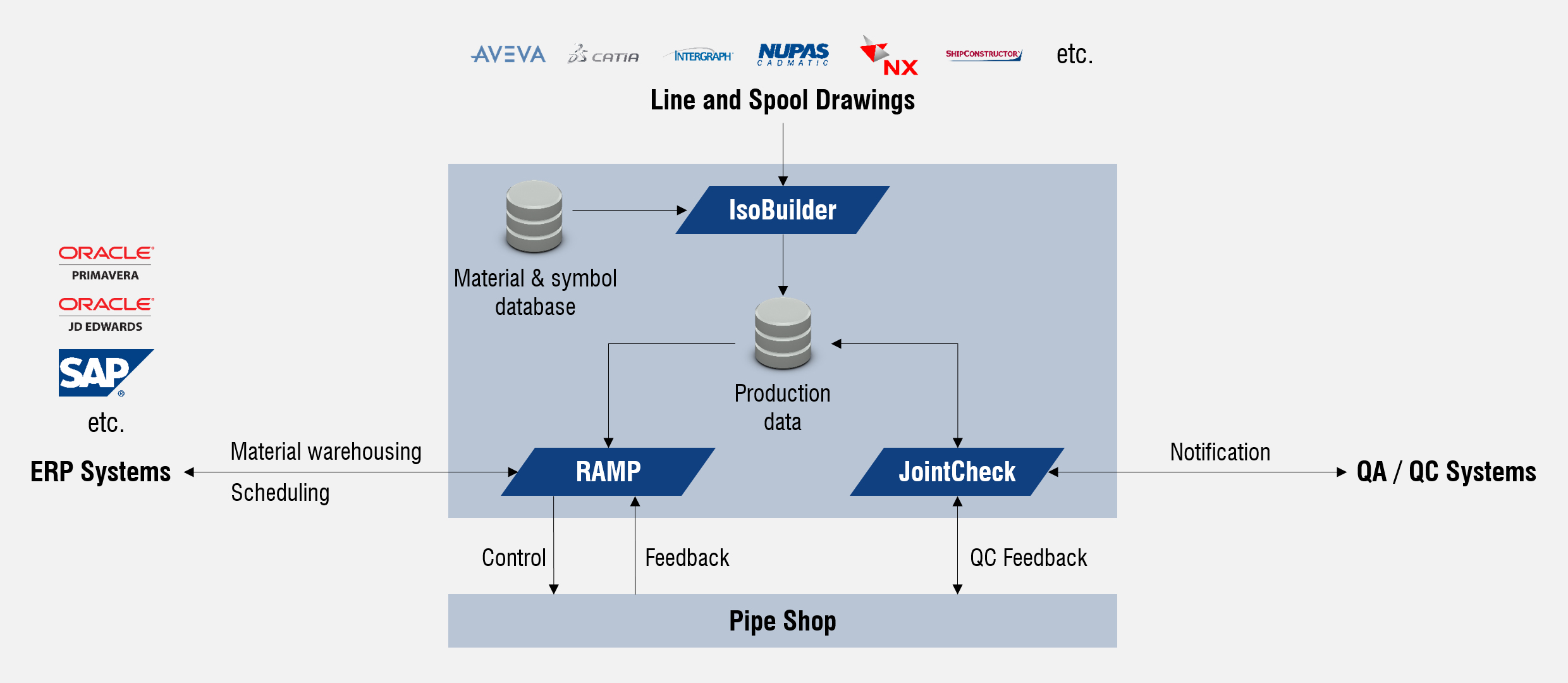

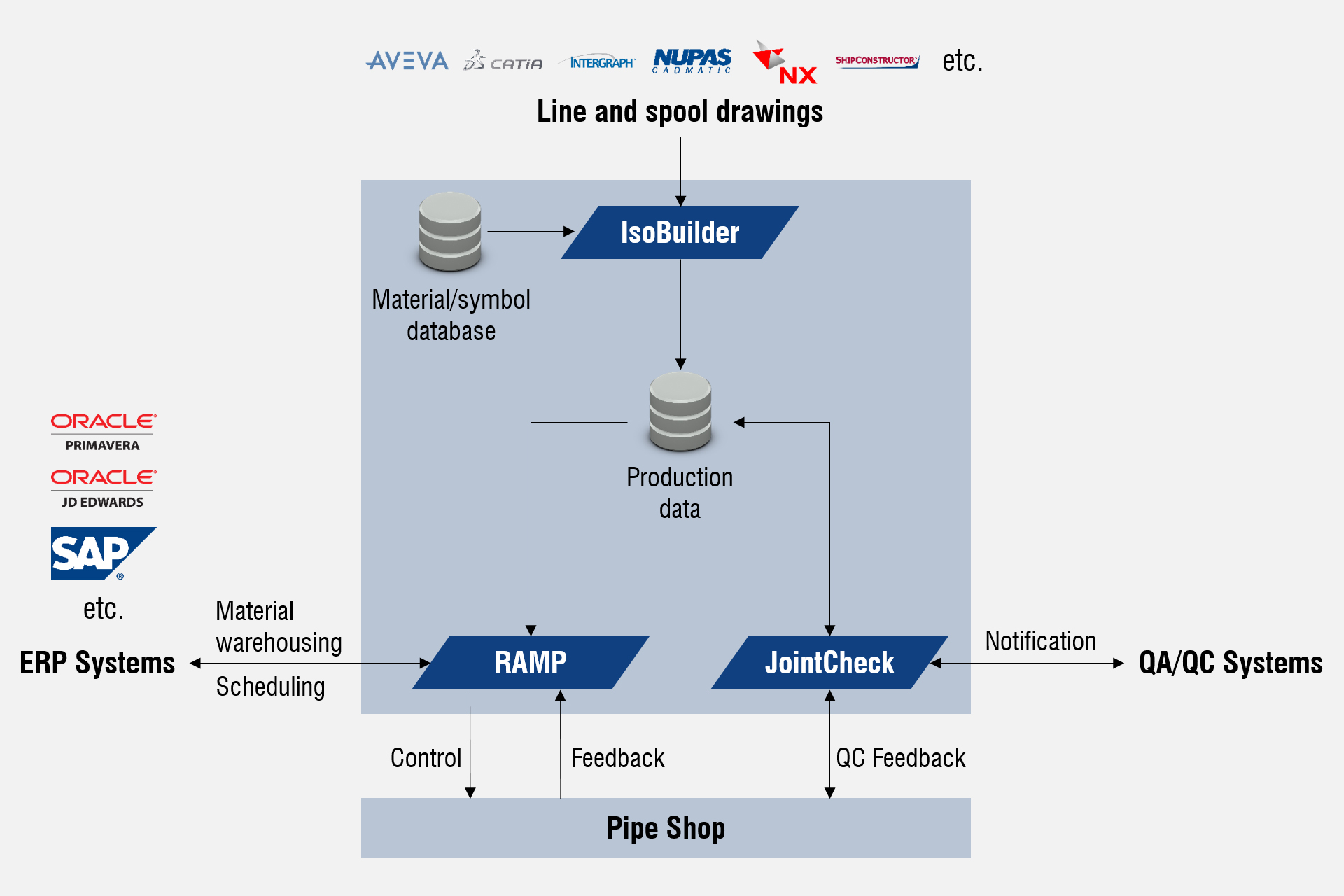

Software Framework

Software Framework

Software for Pipe Spool Production

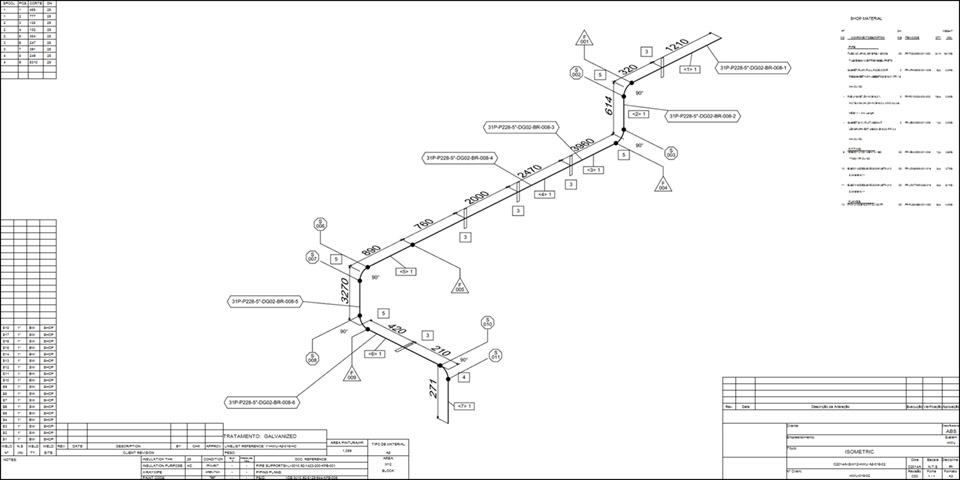

Iso Builder

- Creation/import of line/spool drawings

- Automatic splitting of line drawings into spools

- Automatic exchange of elbows with cost-saving bends

- Maximization of automatic welds

- Automatic generation of reports (dia inch, BOM, worksheets)

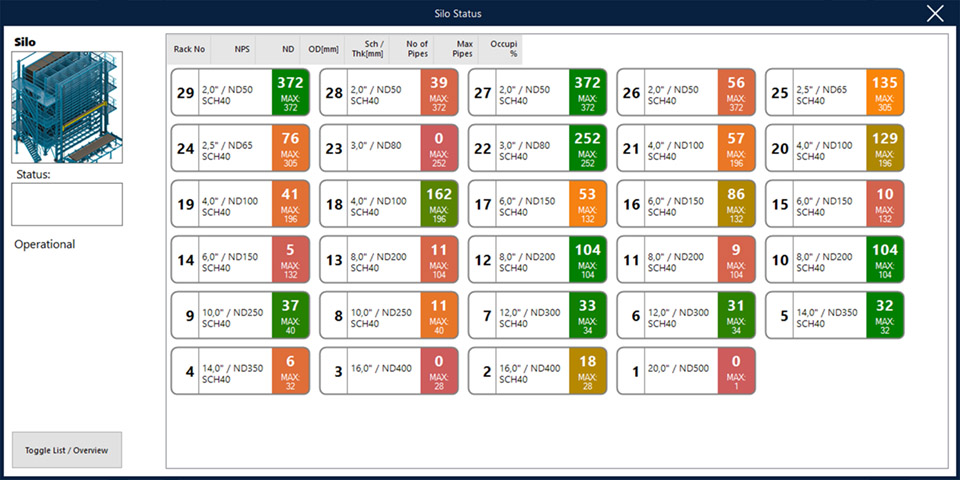

RAMP

- Production planning and monitoring

- Material management

- Scheduling of production

- Workload balancing

- Reporting of production/history data

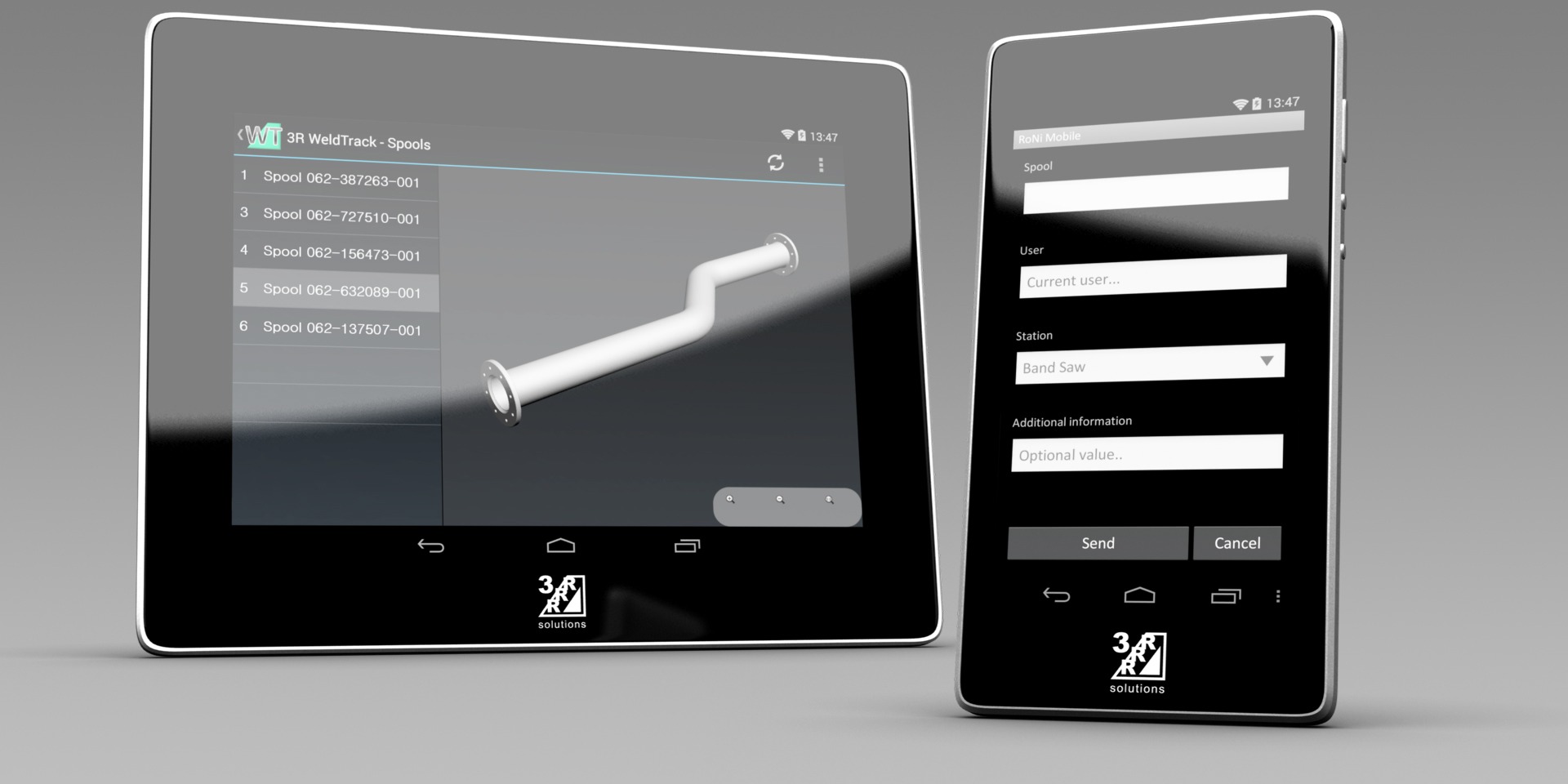

- Tracking of spools until installation

- Generation and transmission of CNC data

Joint Check

- Tracking of fit-up/welding information

- Information forwarding to 3rd party systems

- Available as web-based or client-based application

- Support for typical QA/QC mandatory information

- Automatic generation of QA/QC reports

- Automatic generation of performance reports

Production Control

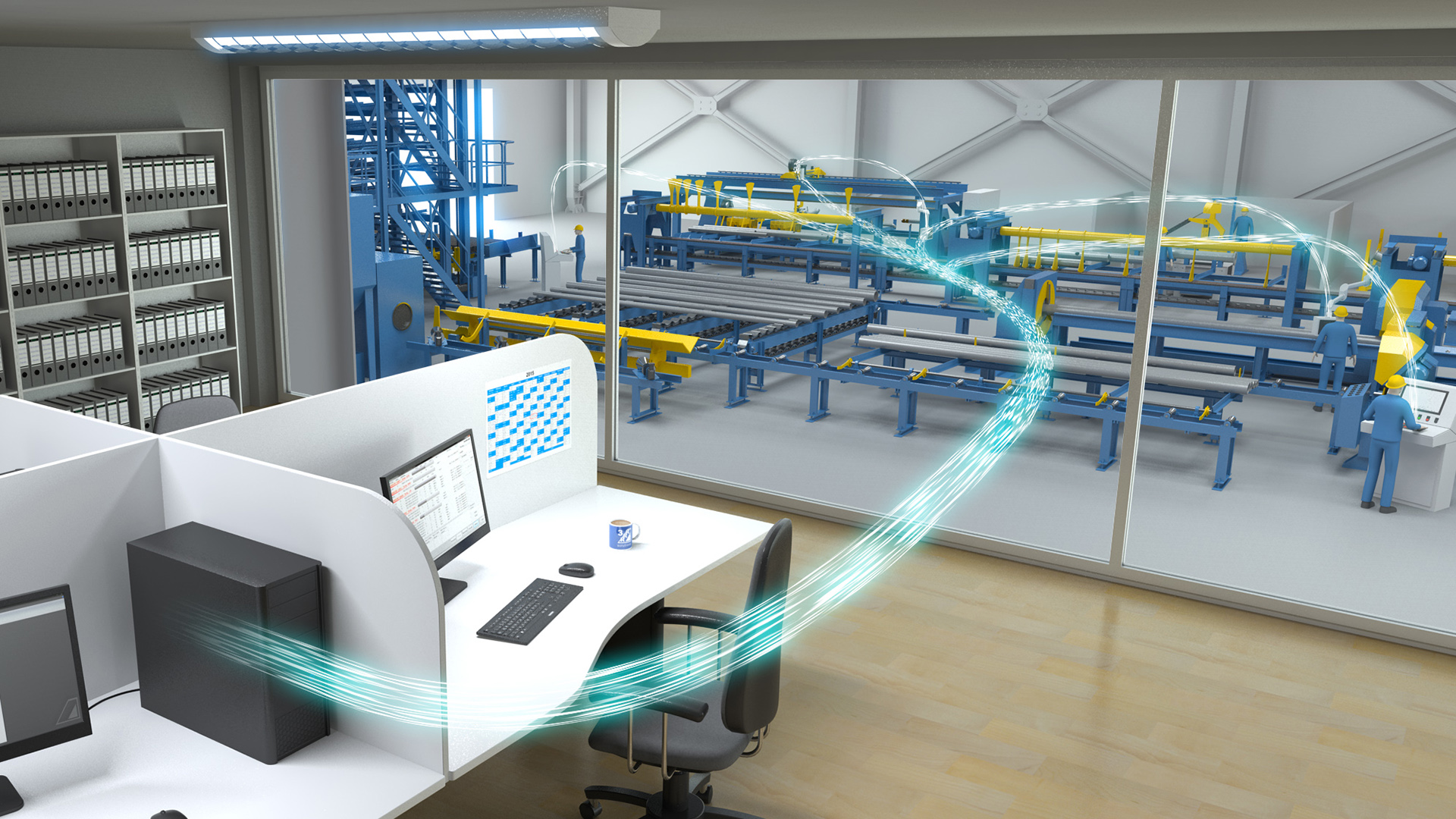

The best pipe-shop design and the best machines in the world still require a software system to control their interaction. A machine for hundreds of thousands of Euros should never have to wait for material, but neither should it have to wait for the operator to calculate the data he needs to enter, so the machine can process the pipe.

In addition it is important to ensure that the material for each day’s work order is available, and that the overall fabrication scheduling is optimized. Spools that are required for installation at an earlier date need to be prioritized over spools that will be installed later, and would take up valuable space for interim storage.

The 3R software is designed to support the entire process chain, from initial design and planning to final reporting, with full traceability of all workshop processes. In addition it provides all data for the CNC machines, as well as digital worksheets for the fitters and welders, cutting lists, bills of material, bending and welding data, and a testing plan for non-destructive testing.

All data is stored in a centralized database, which is updated in real time whenever a worker finishes a task, giving constant, up-to-date status information for all spools and machines.

Production Control

The best pipe-shop design and the best machines in the world still require a software system to control their interaction. A machine for hundreds of thousands of Euros should never have to wait for material, but neither should it have to wait for the operator to calculate the data he needs to enter, so the machine can process the pipe.

In addition it is important to ensure that the material for each day’s work order is available, and that the overall fabrication scheduling is optimized. Spools that are required for installation at an earlier date need to be prioritized over spools that will be installed later, and would take up valuable space for interim storage.

The 3R software is designed to support the entire process chain, from initial design and planning to final reporting, with full traceability of all workshop processes. In addition it provides all data for the CNC machines, as well as digital worksheets for the fitters and welders, cutting lists, bills of material, bending and welding data, and a testing plan for non-destructive testing.

All data is stored in a centralized database, which is updated in real time whenever a worker finishes a task, giving constant, up-to-date status information for all spools and machines.

Additional Software

Kolli

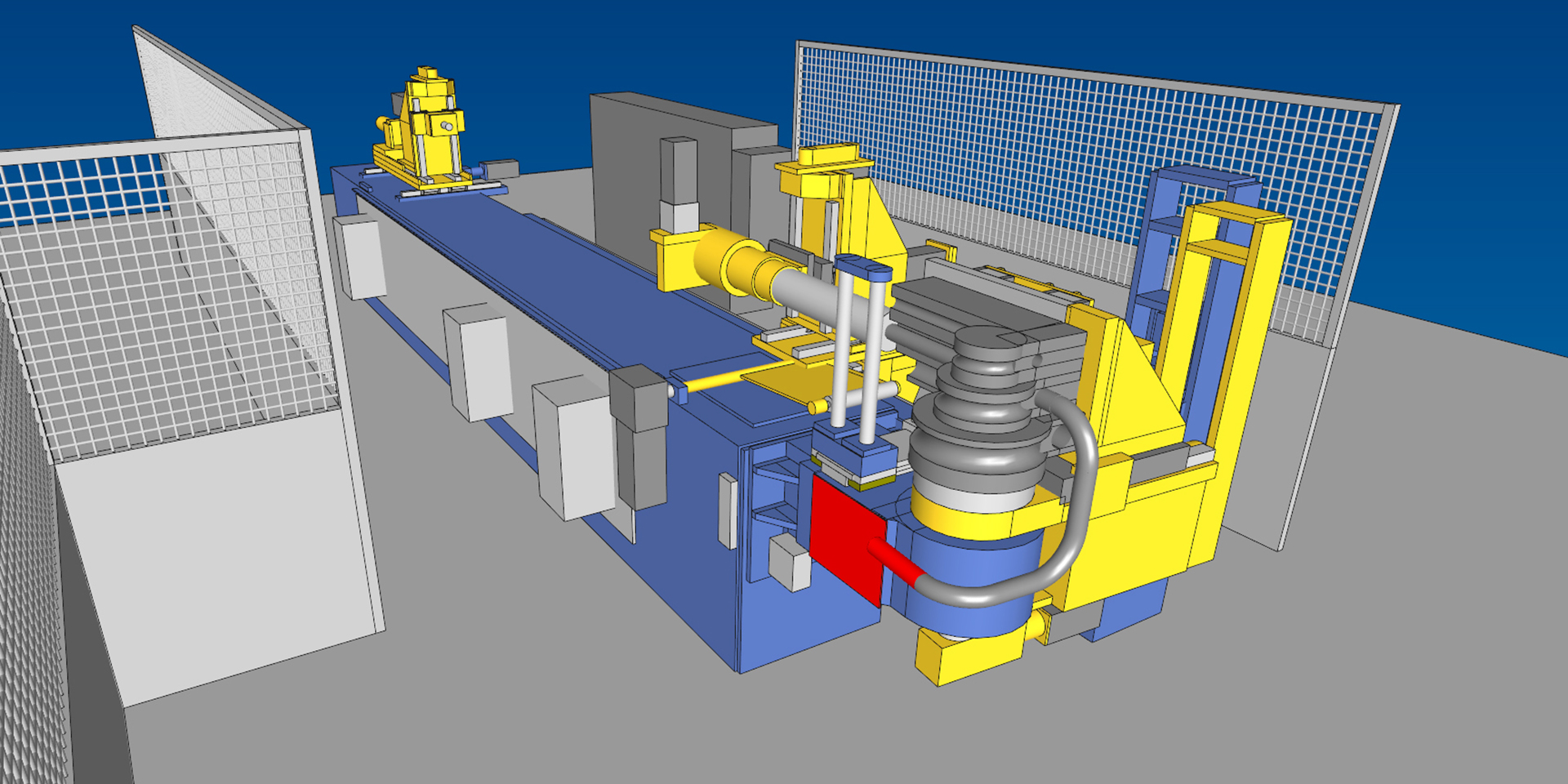

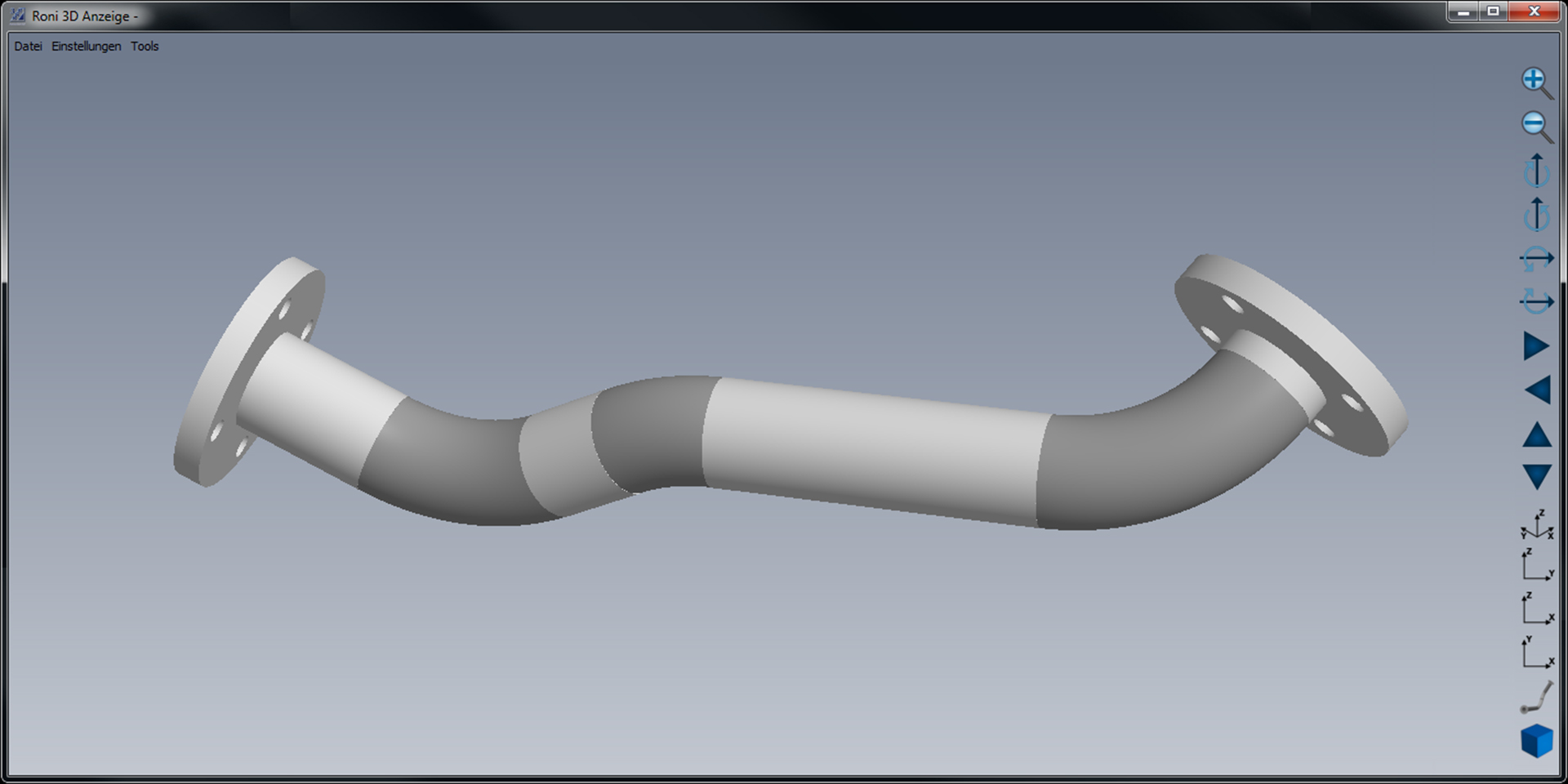

- Collision detection with automatic adjustment of bending process

- Simulates multiple bending heads and levels

- Supports mandrel and roller bending machines

- Simulates bending with flanges

- Generation and transmission of CNC bending data

- Import from 3rd party CAD systems

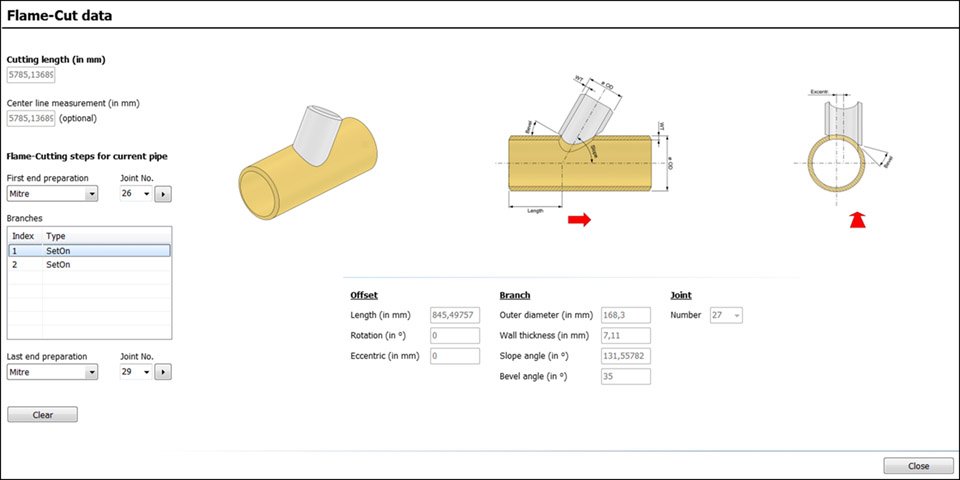

Spool editor

- Catalogues for customer-dependent material storages

- Automatic generation of CNC flame-cutting data

- Extended welding information

- Customizable user administraton

- Interface to pipe bending simulation Kolli

Tube Fit

- Convenient measuring of fitting pipes

- High-precision data recording

- Increased range through reference system

- Checking and correction of bending data